Our policy toward "quality control" is nothing but to always recognize the attainment

conditions of each Certification / Licensing and to maintain those Certifications

/ Licensing. Our mission is to continue supplying medical equipment parts and products.

In order to do so, we have been trying to have as many verification opportunities as possible which include

customer’s audit and our internal audit, regular quality control meetings with a customer, and an early

detection of potential problems through customer satisfaction surveys.

"To meet customer’s satisfaction with our global quality technology / expertise"

Both products and QMS are aimed to maintain "Medical Grade".

Moreover, even if any failure occurs, we will thoroughly investigate the true cause and

disclose the problems and the progresses. We have established a mechanism to verify the issue and

we have been operating to prevent any recurrence.

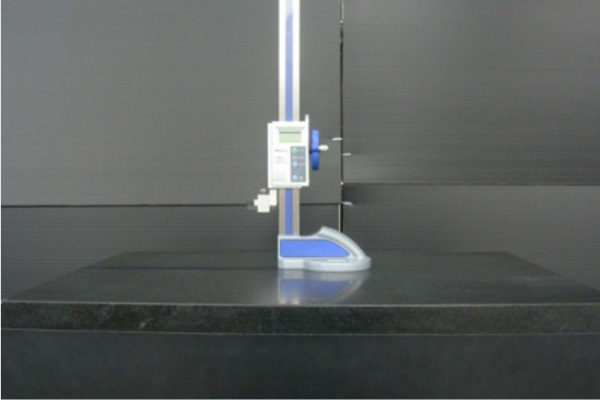

In order to submit accurate data / results to customers, we do proper calibrations from large equipment such as X-ray radiation shielding room for medical equipment and 3 dimensional measuring devices of micron orders to small equipment.

3-dimensional measuring device

Thermostat chamber

Shape measuring instrument

High voltage tester

Color-difference meter

Plate and height gauge

3D Printer

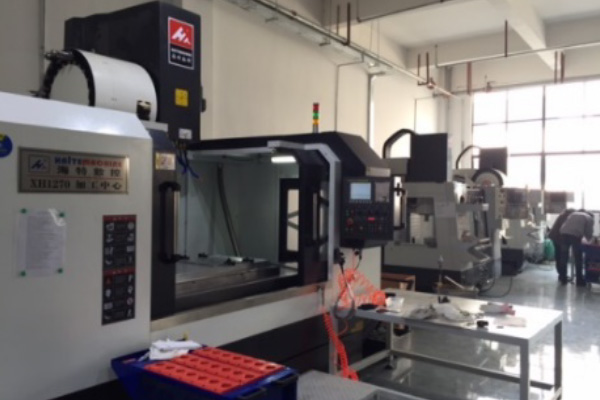

Production site of China factory

Production site of China factory Example of excluding wastefulness

Example of excluding wastefulness

CNC equipment

CNC equipment

*Manufacturing equipment such as CNC machines or welding machines placed and picked in consideration of productivity and safety which would meet customers’ demands.